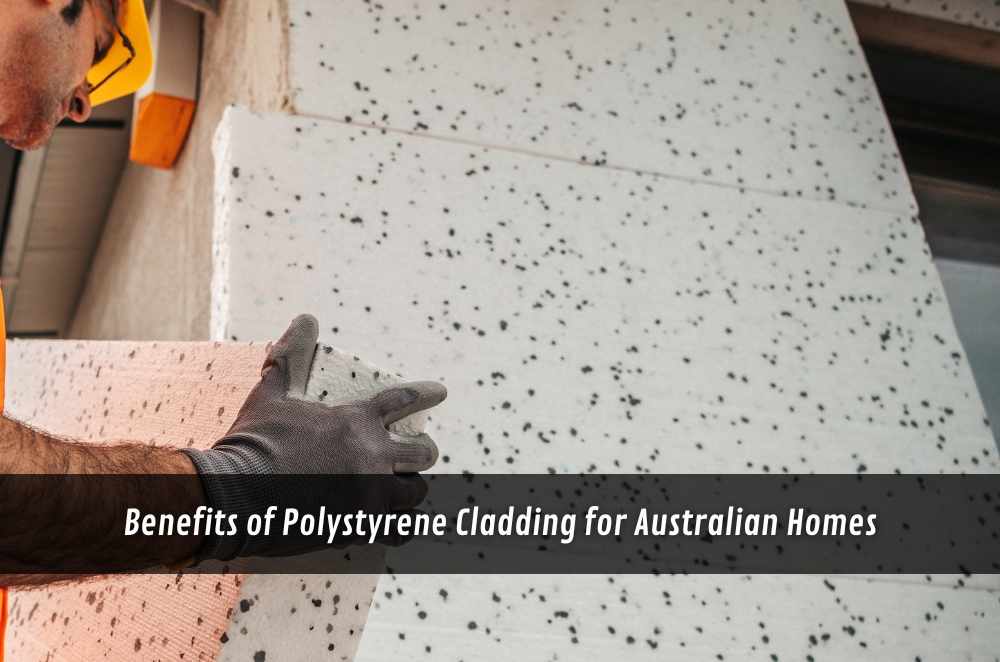

Builders chase two things: speed and performance. Polystyrene cladding, when done appropriately, delivers both without punishing your budget or the site schedule. It’s light, insulates well, and goes up fast, which means fewer trades bottlenecks and less crane time. On tricky blocks or second-storey projects, the difference is night and day. If you’ve wrestled with heavy panels, you’ll know why crews prefer more innovative systems like this. For a clear picture of the workflow, see our lightweight polystyrene wall systems, which make construction efficient. That promise isn’t marketing fluff; it’s about practical detailing—mesh, beads, render coats—working together so walls look sharp, stay warm, and shrug off the elements in real Australian site conditions.

Across suburban infill and coastal builds, polystyrene cladding solves headaches that slow jobs and drain profits. The panels are easy to cut, minimise waste, and reduce the number of hands needed on the wall. Render systems bond well, giving that crisp, modern finish buyers want without adding a ton of weight to balconies or upper floors. Thermal and acoustic gains are real: fewer cold spots, less street noise, and happier clients come handover. Maintenance isn’t scary either; a sensible repaint cycle and quick crack repairs keep façades tidy for years. In short, this isn’t a fad material. It’s a pragmatic path to cleaner lines, warmer rooms, and tighter programs.

What makes polystyrene cladding worthwhile?

It balances low weight with strong thermal performance, making installs faster while improving comfort. The key is pairing quality boards with the right mesh, trims, and render.

On sites with limited access, crews move panels by hand, cut on the fly, and stay productive when the weather turns. Fixings don’t demand monster frames, so engineering stays straightforward and costs predictable. For homeowners, the energy savings and quieter interiors are tangible. For builders, the real kicker is consistency, clean corners, fewer callbacks, and finishes that hold up. If you’re weighing options, these polystyrene cladding advantages clarify where the system shines.

• Cuts crane time and labour pressure

• Adds thermal performance without bulk

• Clean render lines suit modern designs

How does it perform on Aussie homes?

Well in heat and cold, provided detailing is tight. Good sealing, correct beads, and breathable coatings keep moisture moving the right way.

Bush suburbs, salty coasts, city terraces—each asks something different of an external wall. EPS with reinforced render answers by blocking heat gain, reducing winter heat loss, and softening traffic noise. The surface takes colour evenly, so design choices aren’t limited to off-the-shelf textures. Just respect the basics: window flashings that kick water out, control joints where spans change, and sealants that tolerate movement. Do that, and you'll get a façade that still looks fresh even after the landscaping has grown in.

• Suits extensions and second-storey additions

• Lighter loads help older foundations

• Straightforward maintenance cycles

What’s the bottom line?

Choose polystyrene cladding if you want speed without selling out performance. It rewards careful detailing with warmer, quieter, better-looking homes—and keeps build schedules under control.

We’ve seen the material mature from “alternative” to go-to. The trade-off is straightforward: plan your penetrations, specify known render systems, and monitor sealants during the first year. By doing that, owners get the comfort they can feel on day one, along with power bills that don’t bite. The benefits of polystyrene cladding it is worth a look.

Write a comment ...